The volume range of our rear loaded RCVs spans from 10 up to 30m3. The vehicles are designed to best meet the current demand for pay-as-you-throw and door-to-door services, while maintaining high safety standards. Thanks to their simple construction, all models in the SP series are particularly long-lasting.

Scroll

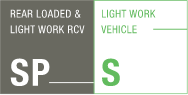

SPS LIGHT WORK, with a body capacity ranging from 10 up to 16 m3, this rear loaded RCV has peculiar characteristics that make the collection work "lighter" and safer.

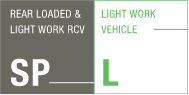

SPL LIGHT WORK, with body volumes ranging from 16 up to 22 m3, this rear loaded RCV has peculiar characteristics that make the collection work "lighter" and safer.

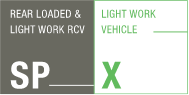

SPX HARD WORK, with a body capacity ranging from 22 up to 30m3, this rear loaded RCV has specific characteristics that make make the collection work "lighter" and safer.

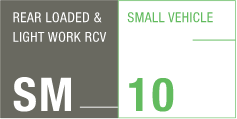

SM 10 is the monocoque model by AMS, with an available capacity of 8, 10 m3. The SM 10 is perfect as a satellite vehicle and particularly suitable for historic city centres and restricted traffic contexts.

The choice of special steel alloys, along with an optimized design, allowed us to achieve a reduced tare to the full advantage of the final payload.

Container/bin lifting device available in several different versions.

Wide hopper suitable for any type of service and conferment, either manual, by means of containers, or for industrial waste collection.

Articulated single-plate packer, exclusive AMS patent.

Type-approved rear footboards for the operators.

- Centralized lubrication system.

- Automatic enzyme-based bin sanitation system

- Dust suppression system

In compliance with the current regulations, the SP compactor is equipped as standard with a rear view camera paired with a TFT-LCD anti glare colour display monitor in the cab, which is always active throughout all the work phases. The CCTV system includes a dedicated audio communication channel from the operator to the driver.

The control system is equipped with a Siemens PLC of proven reliability. The electrical panel is located on the right hand side of the bodywork, which makes it easily accessible for maintenance. The in-cab touch screen allows for direct diagnosis of the correct operation of all on-board components.