Scroll

AMS was founded in 1971 by the Ghetti family, which had already been present in the market of Iveco industrial vehicles for decades.

Their main target was to produce forklift equipment.

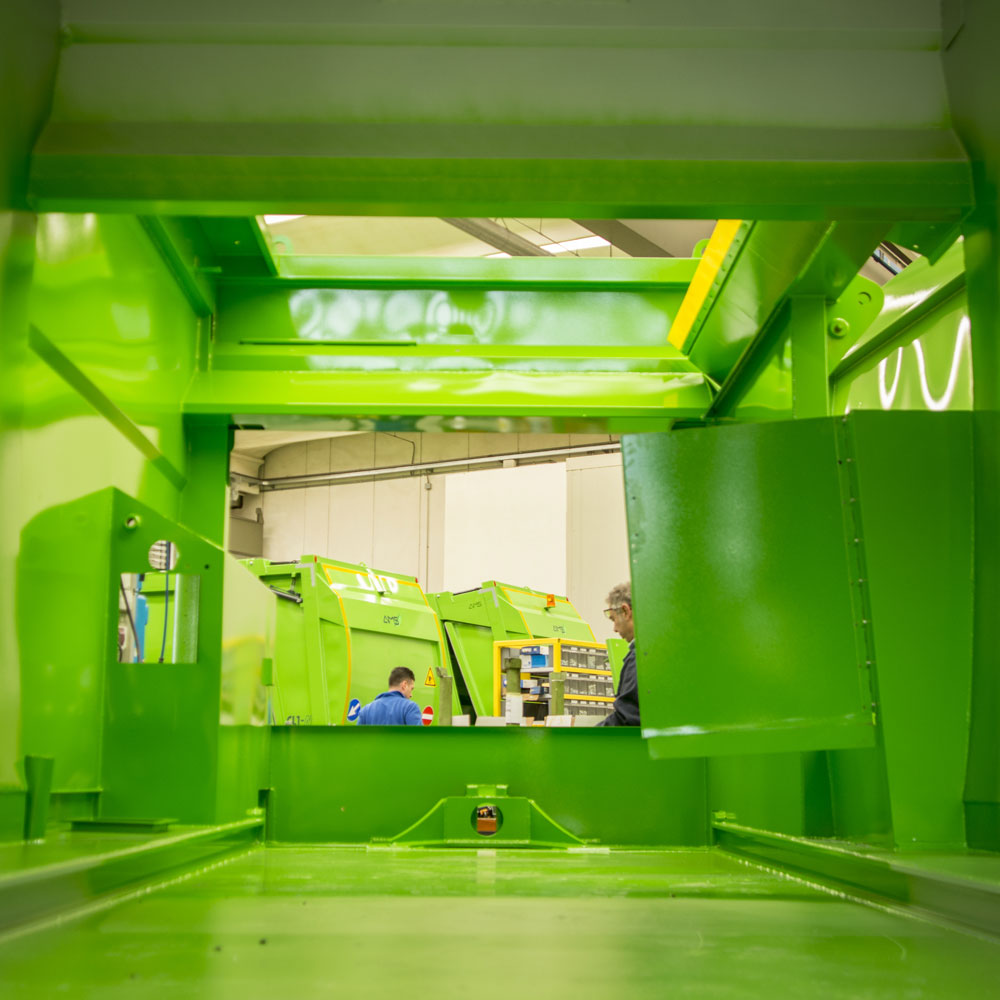

Later on, thanks to the experience gained in the sector, AMS also started manufacturing semi-trailers equipped with aluminium cargo beds, hydraulic lifting ribs, truck-mountable containers and tippers for medium and large vehicles.

In 1983, in light of the additional knowledge acquired in the field of industrial vehicles, AMS expanded to the sector of urban hygiene equipment. Together with some partners, they started producing small compactors for the collection and transport of urban waste. In just a few years, AMS developed an in-house production line, which marked the beginning of a long path towards the creation of its own range of rear loaded RCVs.

In 1993, AMS designed and built a new side-loaded automatic compactor that is still in production to this day, which led AMS to become one of the most renowned companies in the waste management industry.

In the early 2000s, AMS changed its business name becoming a joint-stock company and obtained the ISO9001 certification during the same period.

Thus far, AMS has produced and put on the market thousands of vehicles, including over 1,500 CL1 side loaded models, universally recognized as the most reliable on the market.

The list of patents filed over the decades is a testament to AMS' commitment to innovation in developing cutting-hedge waste collection solutions.

Our goal is to produce efficient, reliable and economically sustainable vehicles. For this reason, we develop simple and long-lasting engineering solutions, designed to achieve maximum performance while reducing costs and consumptions, with no need for constant maintenance.

Waste management requires continuous work cycles with fixed returns: it is therefore essential to ensure a perfect integration between the vehicle and its loading, compaction and discharge mechanisms.

The work cycle must also be carried out with utmost simplicity and safety: manageable control systems and ergonomic layouts will guarantee the necessary degree of security to the benefit of operators.

Respecting the urban context is just as fundamental: the physical and noise impact of the collection and compaction operations must be kept to a minimum.

Waste management and, more generally, how to control the impact of human activities on the planet, are among the most crucial issues of our time.

In fact, we are now fully aware that each of our actions generates both visible and invisible waste, and therefore bears consequences on the environment that surrounds us.

AMS firmly believes that environmental responsibility does not only imply developing waste management solutions and producing increasingly efficient equipment, but also to do so with the lowest possible environmental impact.

This is why our production plants are also increasingly oriented towards maximum environmental sustainability and resource recovery:

Rainwater collection and reuse system;

LED lighting system;

Pellet heating system in all common areas;

Warehouse heated by means of radiant panels;

Reforestation of the adjacent river banks, currently in progress;

AMS is also committed to the development of products that are compatible with the use biodegradable oils;